Features:

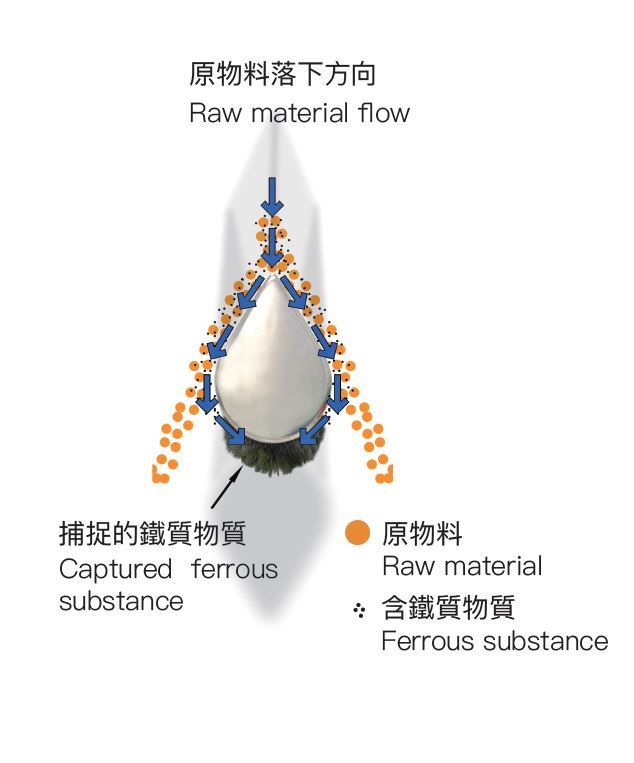

1. Reduce Product Build-up

The distinctive and aerodynamic shape of the waterdrop bar greatly reduces the risk of product bridging/build-up and consequential product stream blockage. Product bridging and build-up increase the likelihood of collected metal re-contaminating the product stream, so it is critical that this risk is minimized where possible.

2. Improve Product Flow & Maintain Product Characteristics

The shape of the magnet allows the product to flow smoothly around the magnet with minimal impact on the product characteristics. Due to the special contour of the bar, an extremely aerodynamic transition of product flow and magnetic fragment retention area is achieved in dry applications where the product is conveyed pneumatically - with minimal to no bulk density effect.

In the case of liquid or viscous applications, the design provides a very hydrodynamic passage of product flow, therefore reducing the risk of product build-up and loss of collected magnetics.

3. Reduce Re-Contamination Risks

When installed correctly, with the point of the Waterdrop magnetic bar directed towards oncoming product flow, captured magnetics are moved to the back of the bar where they are retained on the magnet away from the flow - this is key to reducing the risk of re-contamination.

4. Maximum Product-To-Magnet Contact

The pointed edge of the bar separates the flow and maximum product-to-magnet is achieved, whilst maintaining laminar flow. The longer the dwell time of product in contact with the magnet, the less chance a metal fragment has of escaping and continuing through the process with the product.

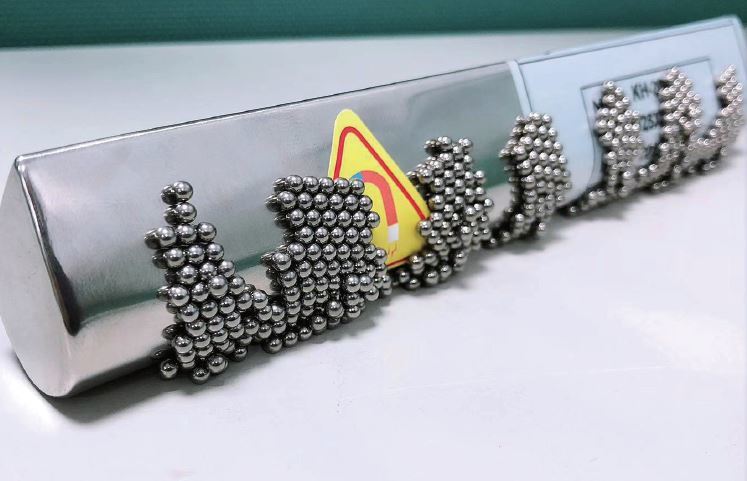

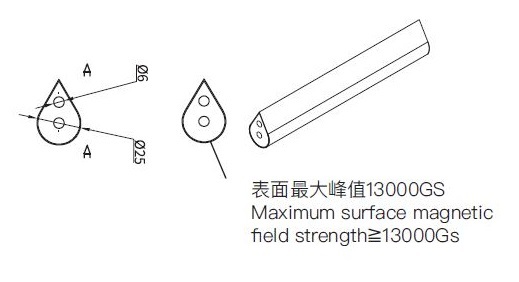

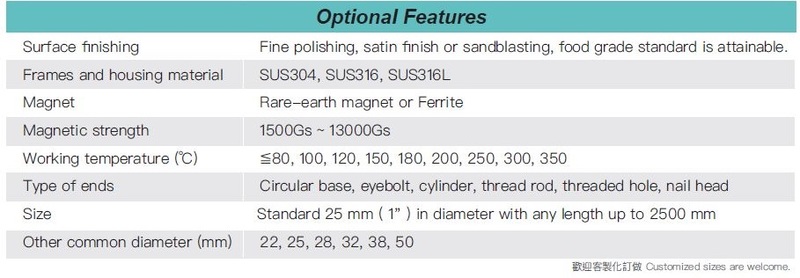

5. High Strength

The Waterdrop magnetic bar includes high-intensity 13,000 Gauss which assures of long-term magnet strength life, and resistance to oxygen absorption and resonant vibration (which are key causes of demagnetization in conventional rare earth magnets).